What is the difference between HDPE and LLDPE geomembrane?

Release time:

2024-06-07

In summary, the choice between HDPE and LLDPE geomembranes largely depends on the specific project requirements, including the need for chemical resistance, flexibility, temperature exposure, and installation considerations.

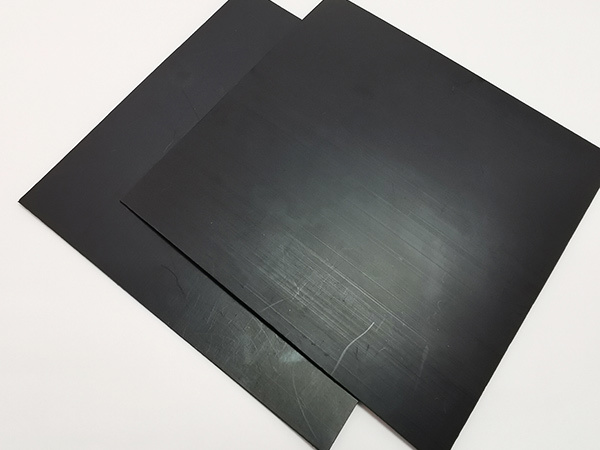

HDPE (High-Density Polyethylene) and LLDPE (Linear Low-Density Polyethylene) geomembranes, while both belonging to the polyethylene family, exhibit different properties that make them suitable for specific applications. Here's a comparison of their characteristics:

HDPE Geomembrane:

1. Density: As the name suggests, HDPE has a higher density compared to LLDPE, resulting in a more rigid structure. This gives HDPE geomembranes better tensile strength and puncture resistance.

2. Chemical Resistance: HDPE generally offers superior chemical resistance, making it more suitable for environments exposed to harsh chemicals, solvents, or acids.

3. Temperature Resistance: HDPE geomembranes can withstand a wider range of temperatures without significant deformation, making them more suitable for applications in extreme climates.

4. Installation: Due to its higher stiffness, HDPE geomembrane might require more care during handling and installation, especially in cold weather when it becomes less flexible.

5. Cost: Historically, HDPE geomembranes have been less expensive than LLDPE, although this can vary depending on market conditions and specific product formulations.

LLDPE Geomembrane:

1. Flexibility: LLDPE geomembranes are more flexible and elongation resistant than HDPE. This increased flexibility makes them easier to install, especially over uneven surfaces, and they are less prone to cracking in cold weather.

2. Impact Resistance: LLDPE offers better impact resistance and tear resistance, which can be beneficial in applications where there is a risk of physical damage from rocks, roots, or heavy equipment.

3. Weldability: LLDPE geomembranes are often considered easier to weld due to their lower melting point, which can lead to faster installation times and potentially fewer defects.

4. Chemical Resistance: While still providing good chemical resistance, LLDPE is generally less resistant to certain chemicals compared to HDPE, making it less suitable for applications involving highly corrosive materials.

5. Cost: Depending on the specific grade and application requirements, LLDPE geomembranes might be more expensive than HDPE, reflecting their enhanced flexibility and ease of installation properties.

In summary, the choice between HDPE and LLDPE geomembranes largely depends on the specific project requirements, including the need for chemical resistance, flexibility, temperature exposure, and installation considerations. Both materials offer reliable containment solutions but excel in different aspects, making them tailored for diverse applications across industries.

Latest News

Why Durable Oil Containment Geomembranes Are Essential for Construction Sites

Why Durable Oil Containment Geomembranes Are Essential for Construction Sites Introduction: The Importance of Oil Containment in Construction In the construction industry, managing materials responsibly is paramount. Among the most significant issues is the risk of oil spills, which can have dire consequences for the environment and public health. Oil containment geomembranes serve as a fundamenta

2026-02-19

Understanding Quality Root Barrier Geomembranes: Essential Insights for Construction Projects

In the realm of construction and landscaping, the use of quality root barrier geomembranes plays a vital role in ensuring the integrity and longevity of structures. Root barriers are specially designed membranes that prevent the penetration of invasive root systems from trees and plants into critical infrastructure. Understanding the significance of these products can greatly enhance the success o

2026-02-16

The Cost-Effectiveness of Investing in Chemical-Resistant Geomembranes: A Comprehensive Analysis

The Cost-Effectiveness of Investing in Chemical-Resistant Geomembranes Table of Contents 1. Introduction to Chemical-Resistant Geomembranes 2. What Are Geomembranes? 3. Types of Geomembranes and Their Characteristics 4. The Economic Benefits of Chemical-Resistant Geomembranes 5. Applications of Chemical-Resistant Geomembranes 6. Investing in Geomembranes: A Long-Term Persp

2026-02-13

Revolutionizing Construction: The Benefits of Customized Floating Cover Geomembranes

Customized floating cover geomembranes are innovative solutions designed for a variety of applications in the construction and landscaping industries. These specialized membranes serve as protective barriers, effectively addressing several environmental and structural concerns. Their unique features make them particularly beneficial in construction sites and water management systems. One of the pr

2026-02-10

Understanding the Essential Role of Customized Biogas Digester Geomembrane in Modern Construction

Understanding the Essential Role of Customized Biogas Digester Geomembrane in Modern Construction In the realm of construction, innovation and sustainability are paramount. One significant advancement that has emerged is the use of customized biogas digester geomembranes. These specialized membranes play a crucial role in enhancing the efficiency of biogas systems and improving environmental susta

2026-02-07

The Benefits of Customized Dam Liner Geomembranes in Construction

In the construction and landscaping sectors, customized dam liner geomembranes are pivotal for effective water management and site protection. These liners are engineered to create barriers, preventing the migration of fluids and protecting the integrity of structures. Customized solutions cater to specific project needs, providing enhanced functionality and improved performance compared to standa

2026-02-04